U.S. Customer’s Top Choice for Multi-Scenario Construction: K3000 PU Sprayer Earns High Recognition

As a professional manufacturer of polyurethane (PU) and polyurea spraying equipment, we are pleased to share a cooperation achievement from the United States: a local customer purchased the professional-grade K3000 Polyurethane Spray & Injection Machine for building insulation and various injection application scenarios. Verified through practical construction, the equipment performed beyond expectations, and the customer gave positive feedback of "the machine worked well, awesome", demonstrating the K3000’s solid strength in professional construction.

K3000: A Professional-Grade High-Efficiency Construction Solution

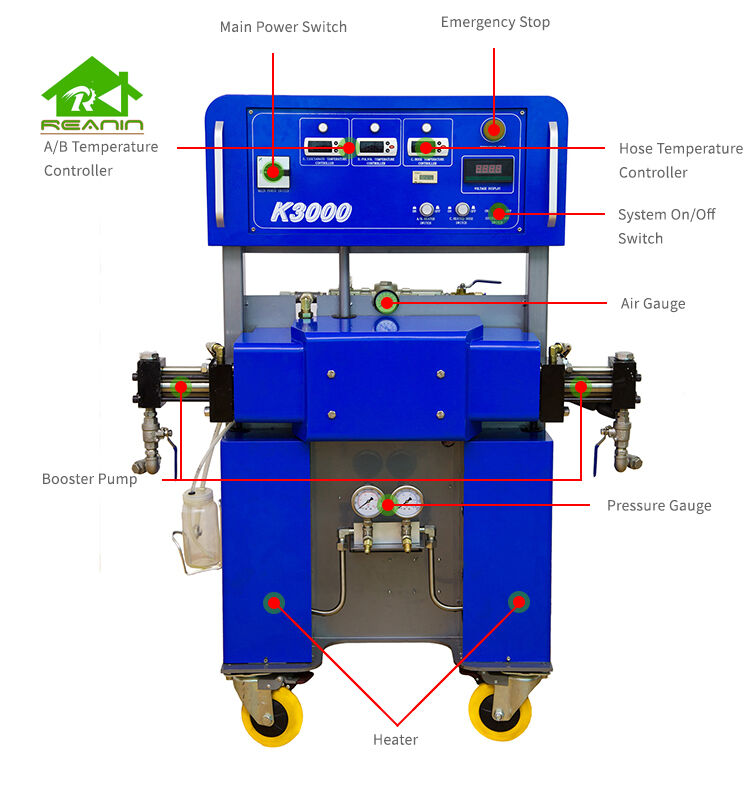

Positioned as a professional-grade cost-effective equipment, the K3000 focuses on stability, efficiency and low maintenance, specifically designed for two-component polyurethane spraying and injection needs. Its unique horizontal booster pump structure not only features small pressure fluctuation and uniform output, but also reduces maintenance costs and downtime significantly due to fewer wearing parts, adapting to professional scenarios in multiple fields such as building insulation and industrial corrosion protection.

For the U.S. customer’s multi-scenario needs, the K3000’s core advantages are precisely matched:

• High-Efficiency Output: With a maximum output of 11kg/minute, the 1:1 raw material ratio is compatible with raw materials of 200-1000 CPS (under working temperature), efficiently completing large-volume construction tasks.

• Convenient Adaptation: The fully pneumatic drive design can operate without electricity at an ambient temperature of around 30℃, with voltage options of single-phase 220V or three-phase 380V to adapt to U.S. power supply conditions; the control panel with operation tips reduces the learning curve.

• Durable and Reliable: The stop-reset function prevents component damage caused by ISO crystallization, extending equipment service life; the action counter accurately calculates raw material consumption to support cost control.

Customized Services + Compliance Support for Global Markets

The key reasons for the customer’s choice of K3000 lie in our free customization service and compliance support. Targeting their multi-scenario construction needs, we optimized the equipment configuration, with a standard 15m heated hose (max extendable to 90m) to meet long-distance and large-scale operation requirements; meanwhile, the K3000 has obtained CE and ISO9001 certifications, fully complying with international standards to ensure smooth customs clearance and quick equipment deployment.

Performance Meets Needs, Feedback Confirms Strength

In building insulation and injection operations, the K3000’s precise temperature control and stable output were fully verified: independent temperature control for A/B material hoses and hoses, combined with variable-frequency temperature control and real-time sensors, ensures stable raw material temperature; the heated hose is covered with a wear-resistant insulating sleeve for leak prevention and heat insulation; full-link filter devices effectively reduce the risk of gun blockages to ensure continuous construction. The customer highly recognized the equipment’s operational stability, ease of use and construction results.

Overview of K3000’s Core Advantages

• Versatile Applications: Covers multiple fields including building insulation and waterproofing, transportation equipment manufacturing, industrial corrosion protection, and electrical specialty applications.

• Worry-Free After-Sales: 1-year warranty + lifelong consulting, full set of spare parts included with the equipment, additional spare parts deliverable via international express in 7 days.

• Flexible Customization: Supports functional optimization and branding customization (logo, color, appearance), welcoming global agent cooperation.

• Precise Control: Pressure gauges in both MPa and PSI units, adapting to usage habits in different regions.

Empowering Professional Construction Worldwide

As a direct manufacturer based in Jinan, Shandong Province, China, we offer competitive pricing, fast delivery (7-10 days for standard orders, excluding customized products), and comprehensive support including English manuals, instructional videos and online guidance.

Contact us today to explore customization needs and let the K3000 empower your project success!