Latvian Customer’s Warehouse Insulation Project Successfully Completed: K2000 PU Sprayer Gains Recognition

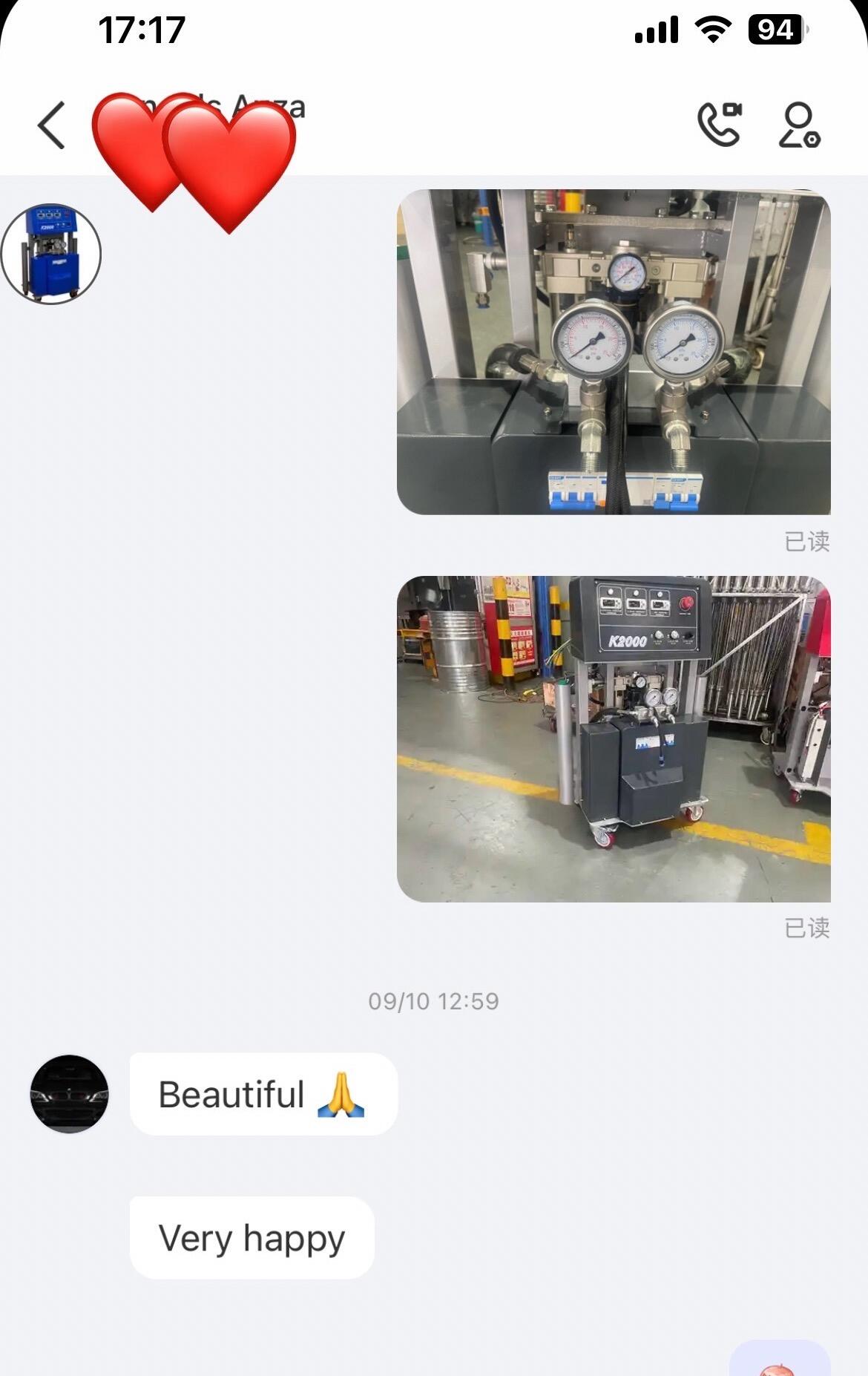

As a professional manufacturer of polyurethane (PU) and polyurea spraying equipment, we are pleased to share a project success story from Latvia. Our best-selling K2000 Polyurethane Spray & Injection Machine has completed an indoor warehouse insulation project for a local customer, who provided positive feedback and an on-site video showcasing the machine’s stable operation and uniform insulation results. This case further confirms the K2000’s practicality and reliability in small-to-medium-scale PU applications.

K2000: A Cost-Effective, Versatile PU Construction Equipment

Designed as a cost-effective and portable solution, the K2000 focuses on practicality and adaptability, making it our most popular entry-level model. Specialized for two-component polyurethane applications, it is capable of both spraying and injection tasks, suitable for various project scales from small renovations to medium-sized industrial projects.

For the Latvian customer’s warehouse insulation needs, the K2000’s core features delivered solid performance:

• Stable Efficiency: With a maximum output of 10kg per minute, the machine can spray up to 2 tons of raw materials per day, meeting project schedule requirements. It adopts a 1:1 raw material ratio and is compatible with raw materials with a viscosity range of 200-1000 CPS (under working temperature), matching the technical demands of polyurethane insulation materials.

• Easy to Operate: Equipped with an intuitive control panel with operation tips, it requires minimal training. The fully pneumatic drive allows operation without electricity at ambient temperature around 30°C, with voltage options of single-phase 220V or three-phase 380V to adapt to different regional power supply conditions.

• Durable and Low-Maintenance: The booster pump has a simple structure for easy disassembly and maintenance; the stop-reset function prevents component damage caused by ISO crystallization, reducing downtime. An action counter accurately calculates raw material consumption to support cost control.

Customized Services and Compliance Support for European Clients

One of the key reasons the customer chose our equipment is the free customization service we offer to all clients. For this Latvian project, we collaborated closely with the customer to optimize the K2000’s configuration for warehouse insulation, including adjusting the layout of the standard 15m heated hose (extendable up to 60m if required) to enhance operational flexibility in large spaces.

In addition, the K2000 has obtained CE certification and ISO9001 Quality Management System Certification, fully complying with European safety and quality standards, guaranteeing smooth customs clearance for the customer and ensuring the machine is ready for use upon arrival.

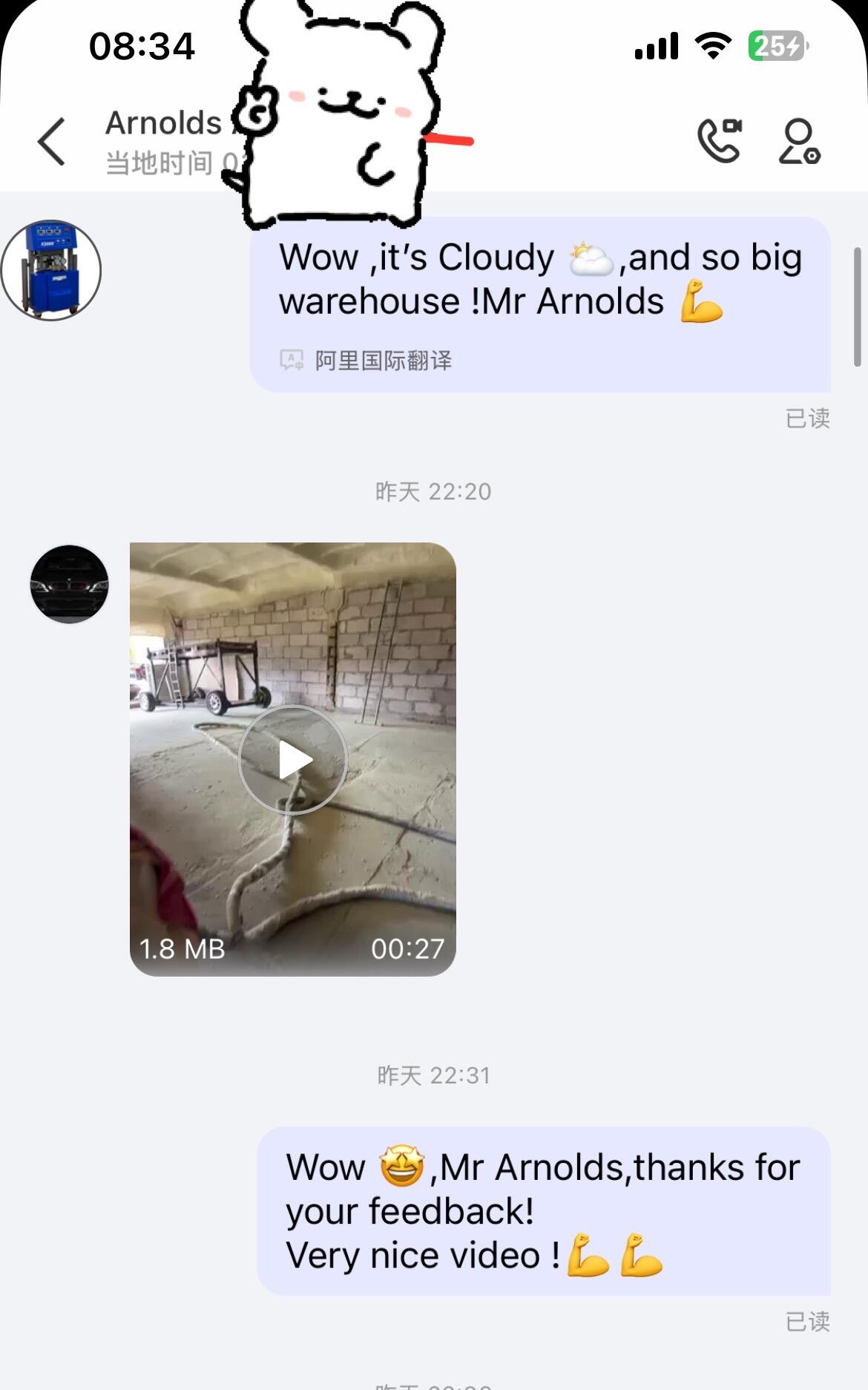

Customer Feedback Aligns with Equipment Performance

After the project completion, the Latvian customer’s shared operation video intuitively demonstrated the K2000’s smooth workflow. The customer recognized the machine’s ease of operation, as well as the insulation layer’s adhesion, waterproofing and thermal insulation effects, noting that the customization service ensured perfect adaptation to the warehouse environment and the CE certification simplified the import process.

This feedback aligns with the K2000’s design features: the integrated heated hose with a wear-resistant insulating sleeve maintains raw material temperature and prevents leakage; independent temperature control for A/B material hoses, combined with variable-frequency temperature regulation and real-time sensors, ensures insulation layer uniformity; filter devices in the transfer pumps, mainframe and spray gun effectively reduce the risk of gun blockages.

Key Advantages of the K2000 for Global Clients

Beyond its performance in the Latvian project, the K2000’s practical advantages make it a reliable choice for clients worldwide:

• Versatile Applications: Suitable for building insulation (roofs, walls, cold storage, etc.), automotive anti-corrosion and wear resistance, infrastructure maintenance (crack injection and joint sealing for bridges, tunnels, parking decks) and industrial equipment/pipeline coating (anti-corrosion and insulation in petroleum, chemical, water treatment industries).

• Compliance and After-Sales Support: Offers a 1-year warranty and lifelong consulting services, each machine is equipped with a full set of spare parts, and additional spare parts can be delivered via international express in approximately 7 days.

• Flexible Customization: Supports functional adjustments and branding customization (logo, color, appearance), and offers local resale cooperation opportunities, welcoming partners to join the global agent network.

• Precise Control: Equipped with high-precision pressure gauges in both MPa and PSI units, meeting the usage habits of customers in different regions.

Support for Your Next Polyurethane Project

The successful completion of the Latvian warehouse insulation project demonstrates the K2000’s stable performance and practicality, backed by our commitment to customized services and global compliance standards. Whether you are undertaking warehouse insulation, building waterproofing or industrial coating projects, the K2000 is a cost-effective choice.

As a direct manufacturer based in Jinan, Shandong Province, China, we offer competitive pricing, fast delivery (7-10 days for standard orders, excluding customized products), and comprehensive support, including English user manuals, instructional videos and online guidance for first-time users.

Contact us today to learn more about the K2000 Polyurethane Spray & Injection Machine, discuss your customization needs, and let us support your project success from customs clearance to on-site construction.